Smart train technology

The basic platform for all monitoring functions

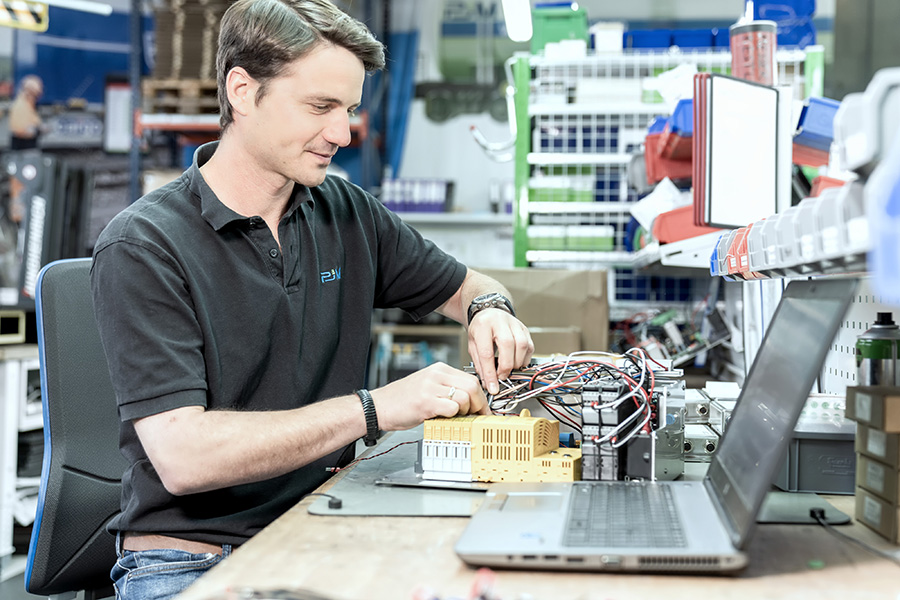

The basic platform for all monitoring functions and automated processes is the overall digital WaggonTracker system, which is installed on the freight wagon.

The technical concept at a glance:

- Power supply: The WaggonTracker system is supplied with sufficient power via a wheel hub generator. An additional battery provides energy during downtimes.

- Sensors and strain gauges record data in real time

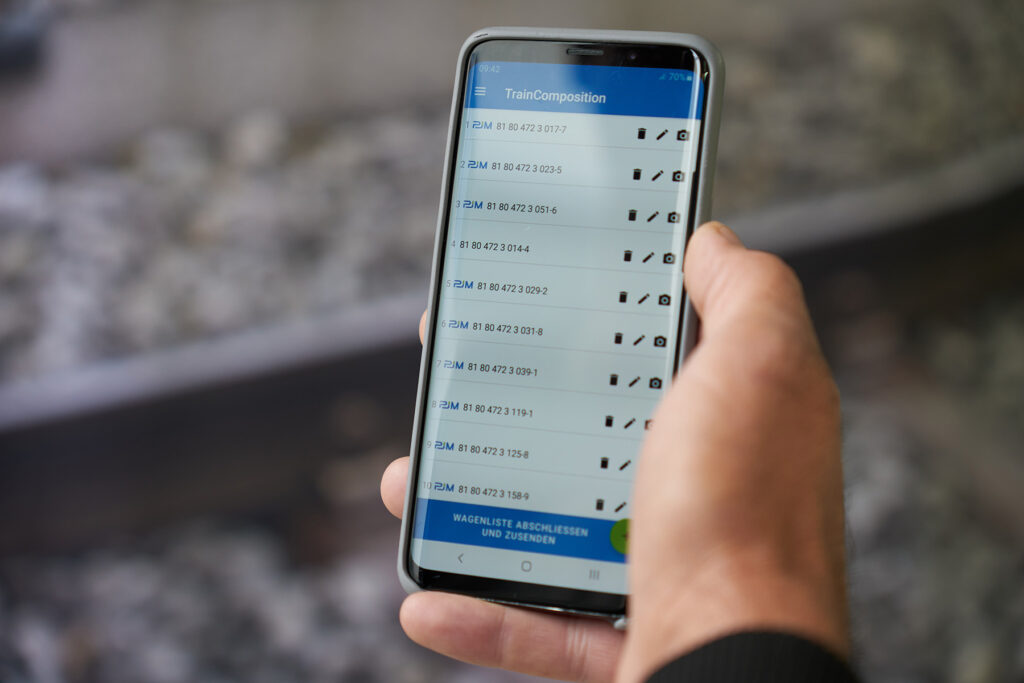

- Data is transmitted in real time within the train formation via a long-range radio system

The basic concept includes:

- Powerful and autonomous power supply: The axle box generator provides sufficient power for all digital train functions. The autonomous and powerful power supply enables a variety of demanding functions such as automatic brake tests and monitoring functions as well as additional systems or future applications such as DAC.

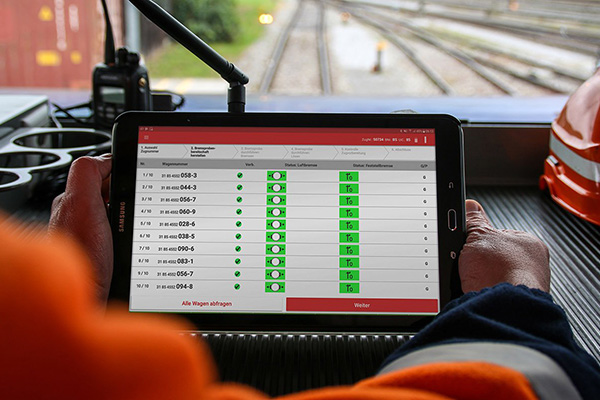

- Monitoring function: Relevant data about the freight wagon is recorded, processed and transmitted to a web service in real time. The data is divided into two categories:

Basic data: Mileage, direction of travel, current position, last message, last movement, historical data.

Sensor data: Loading status, running behaviour, axle bearing temperature, brake system status, brake energy status, derailment status, load weight, shock monitoring, trestle status, ambient temperature and many more - Safety electronics and in-train communication: The safe recording of measurement data in combination with a connection to a central control unit form the basis for the automation of operating processes.

- The in-train communication is based on a long-range radio system that is designed for maximum availability and guarantees an encrypted, secure connection as well as direct communication with the train driver.

- Scalability: The overall digital system is scalable with customised and future applications. The modality of the system makes it possible to integrate any number of sensors, e.g. for axle bearing temperature monitoring.

- DAC-compatible: The WaggonTracker system is compatible with a future digital automatic coupling.

- Fully compatible: The PJM system is also compatible with other customized applications and independent of other technologies or wagon equipment.

- Compatible for all wagon types: The WaggonTracker is suitable for all wagon types and can be fitted out ex works on new wagons or integrated into existing wagon fleets. The system is easy to install, robust and largely maintenance-free. Thanks to its durability and immediate effects, upgrading existing wagons also makes economic sense.

- Simple integration: The WaggonTracker system is easy to integrate into the wagon fleet and upgrading the wagons is simple. The implementation of the upgrade is also flexible: either PJM installs the WaggonTracker system or the wagons are rented fully equipped: The applications are in the equipment portfolio of our partners VTG, TRANSWAGGON or GATX. The largest European wagon manufacturer Tatravagónka supplies wagons with automatic brake testing and all other digital train functions ex works.

- Approved & available technology: The patented WaggonTracker system is an approved technology, already in use at renowned railway companies and now available.

- Monitoring & automation in 1 system: The WaggonTracker is the only system worldwide which combines in-depth monitoring functions and automation in only one system.

- Unique features: Various applications are worldwide unique, among others the Automated Brake Test, kingpin monitoring, derailment detection and brake system monitoring.

Contact:

Felix Egger-Cimenti

[email protected]

+43 676 4048663

Do you have questions about our digital technology?

Simply fill in the form or contact Felix Egger-Cimenti directly.