Smart Train

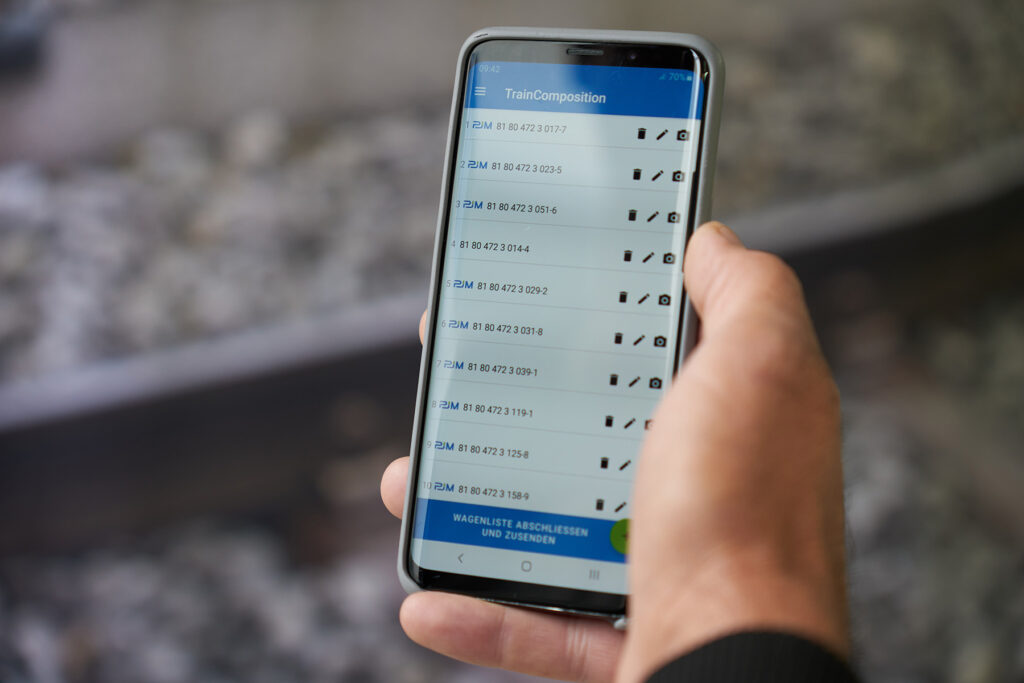

The digital freight train from PJ Monitoring

Digitalisation puts efficiency, cost-effectiveness and reliability on track

Environmentally friendly & competitive freight transport

Intelligent freight trains create cool jobs

Digital rail transport brings safety

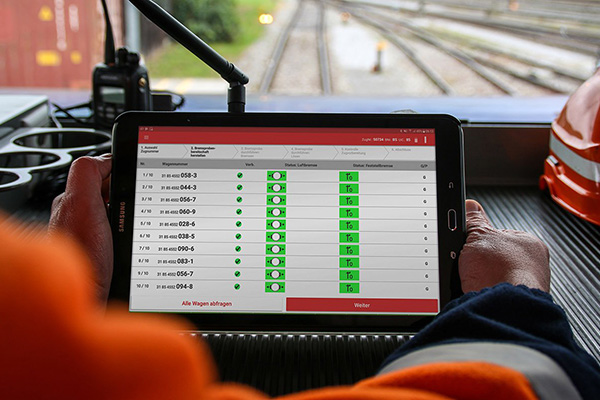

Our digital solution is a system with a double bottom. The digital train and monitoring functions increase safety, both via the application itself (e.g. derailment diagnosis, automatic brake testing, support frame monitoring, etc.), but also via a predictive maintenance strategy, which is made possible by the extensive monitoring functions. Our system is also a guarantee for the future, as it is compatible with future systems (e.g. DAC) and scalable with customer-specific applications. Thus, you can benefit from the many advantages today and at the same time be technologically future-proof.

Digital train functions developed for and with RU and OEM

All functionalities are our technical solution to problems encountered in the everyday work of rail transport companies and Railway Undertakings. We developed the automated brake testing system in collaboration with SBB Cargo and the digital train functions such as support stand monitoring with FS Logistix (formerly Mercitalia). Load monitoring was developed based on the experience of timber shippers and tested for compatibility with DAC technologies in various development projects. An important prerequisite for all our innovations and further developments is our in-depth understanding of rail freight transport and the railway system as a whole.

References

Our digital train functions and automatic brake test are on board SBB Cargo, FS Logistix (formerly Mercitalia Intermodal), Mercer, Lenzing and DB Cargo. Our applications are included in the equipment portfolio of Tatravagónka, Europe’s largest freight car manufacturer, as well as the largest car rental companies VTG, TRANSWAGGON and GATX.

Our automatic brake test has been proven compatible with DAC solutions on multiple occasions. Among other things, in tests conducted as part of the FP5-TRANS4M-R project (report from May 2025 at https://rail-research.europa.eu/latest-news/successful-testing-of-the-dac-with-powerline-train-backbone/) and in July 2025 during live demonstrations of a WLE car equipped with the automatic brake test and a DAK coupling from Voith (a project within the framework of DAC4EU, available at https://www.voith.com/corp-de/news-room/press-releases/2025-07-23_vt-voith-delivers-digital-automatic-coupling-for-the-first-dak-train.html).