Brake system monitoring and real-time brake analysis

Brakes play a particularly important role in rail freight transport, especially in Alpine traffic. They are a crucial component in terms of safety, but they are also a relevant cost factor in maintenance.

Our system determines data on:

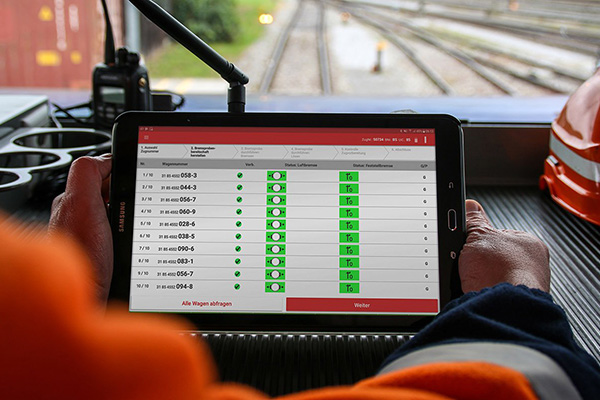

- Correct functionality in terms of HL status and CT pressures to ensure the brakes function correctly during travel and at standstill

- Brake release time

- Brake application (normal / emergency braking)

- Real-time braking energy calculation of each bogie to identify possible damage or flat spots

- Real-time evaluation of measurements in the web portal

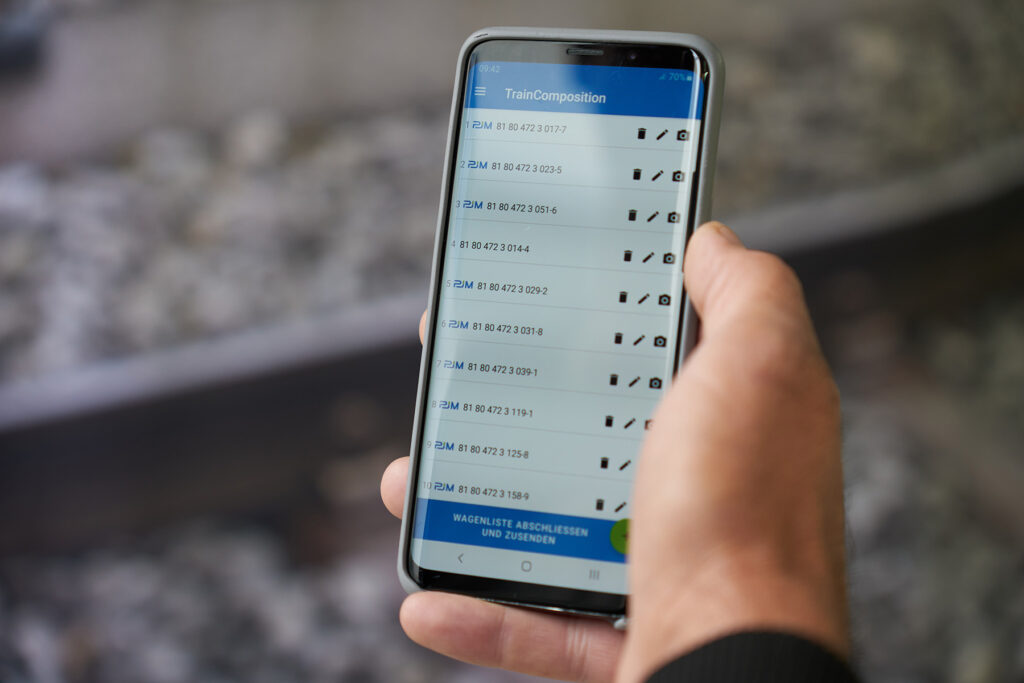

- Real-time notification of the train driver

Relevant information can be derived from this real-time data, such as functionality of the brakes, any incorrect operation, overloaded or defective brakes, wear and tear or how long the functionality will last. The brakes are therefore not only important in terms of safety, but also for the logistics requirements in intermodal transport (just-in-time delivery).

Unplanned out-of-sequence deliveries, which lead to delays and slot losses, must be largely avoided in order to achieve the specified delivery targets and capacities.

Regarding maintenance, this information is relevant in order to be able to plan maintenance with foresight and as cost-effectively as possible. From a safety perspective, this data is essential to ensure safe driving operations (e.g. avoidance of wheelset damage due to thermal overload).

Advantages

- More safety

– Early detection of brake defects (e.g. cradle valve, dragging or sticking brakes)

– Real-time warning to the train driver (e.g. not if brakes are not fully released, overloaded or applied / hand brakes when moving off) - Enhanced efficiency

- Minimization of unplanned outages and therefore more reliable achievement of delivery targets

- Higher quality through preventive and wear-based maintenance of brake blocks by calculating braking energy

- Lower costs through condition-based maintenance & efficient workshop planning

- Lower costs through:

– Reduction of wheelset wear and avoidance of wheelset damage through early detection of brake defects and checking before departure whether all hand brakes are released - Higher availability through minimized acute repairs

- More safety, e.g. by avoiding wheelset damage due to thermal overstress

Contact:

Felix Egger-Cimenti

[email protected]

+43 676 4048663

Do you have questions about our digital technology?

Simply fill in the form or contact Felix Egger-Cimenti directly.