Automatic brake test & semi-automated train preparation

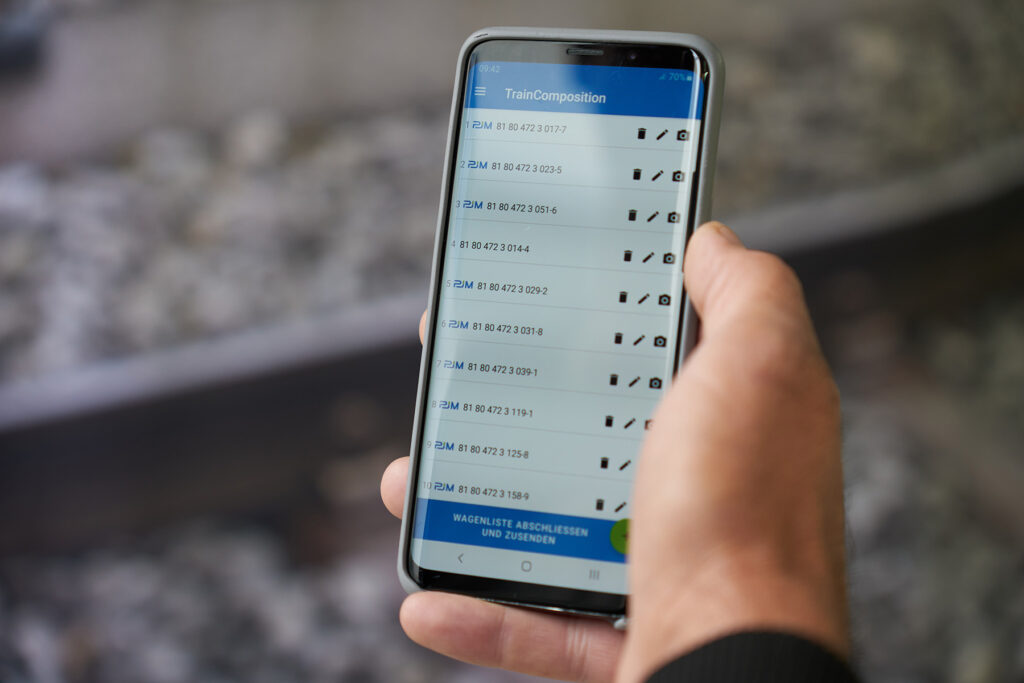

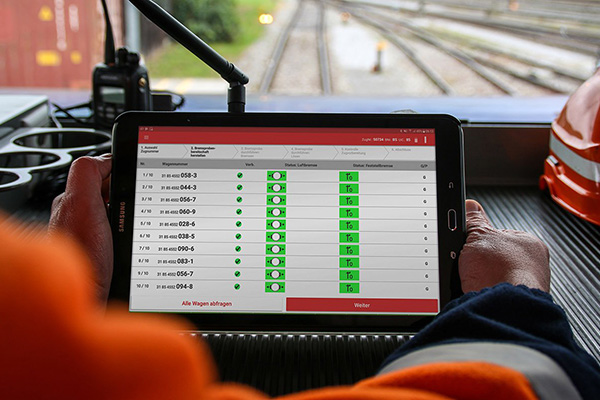

Reliable and safe determination of brake status via tablet

- Brake tests in freight transport are time-consuming, arduous and labour-intensive: in contrast to passenger trains, the brakes have to be checked manually. An employee checks each individual axle to ensure that the brake blocks are applied. The check is necessary every time wagons are detached or the train has been stationary for 24 hours. For a 500-metre-long goods train, a brake check takes around 2 employees around 45 minutes. The PJM system uses measuring sensors to automate this process. A clear evaluation of the brake measurements is displayed on the tablet of the train driver or the person responsible for the brake test.

- The automatic brake test fulfils all safety-relevant requirements in terms of operation and vehicle.

- The brake testing system is the only approved system worldwide and is therefore the European reference system.

– Positive assessment assessed by TÜV Süd: February 2022

– Type approval from the BAV (Swiss Federal Office of Transport): November 11/2023 - The system has been tested over many years and has been in operational use at SBB Cargo since August 2027. Over 200 wagons are now equipped with the system, and a fleet roll-out will follow soon.

- The Automatic Brake Test (ABT) is fully compatible with a future DAC solution. Among other things, a DAC pilot train was equipped with Powerline PLUS communication technology and the automated brake testing system. The pilot train was in operation in Europe from February to December 2023 and travelled over 4,200 km. The ABP performed ‘flawlessly’ in all tests. A summary of the tests can be found at: https://rail-research.europa.eu/latest-news/successful-testing-of-the-dac-with-powerline-train-backbone/

2. The ABP supports train preparation:

- G/P switching

- Train length

- Brake calculation

- Rake check

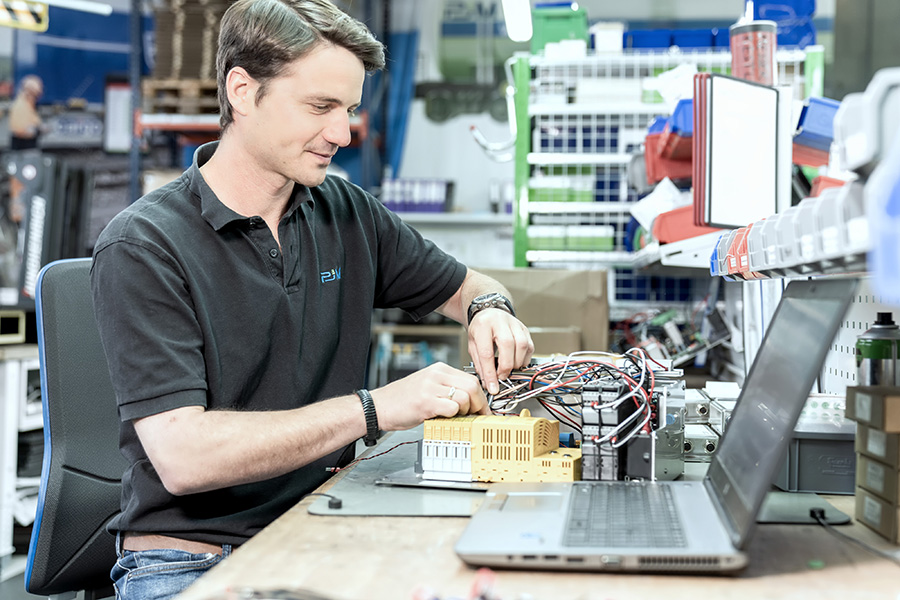

3. The brake testing system is the basis for further functions

- Monitoring the brake components (maintenance)

- Brake monitoring while travelling (faulty braking, train separation, flat spots, etc.)

Advantages of Automatic Brake Testing via tablet

- Faster train preparation – 2 minutes instead of 2 x 40 minutes

- Complete brake testing possible by 1 person

- More safety in the track environment

- More safety for the wagons

– Reliable detection of the brake status incl. handbrake

– Early detection of brake defects - Higher quality in data evaluation

- Higher quality through reliable and reproducible processes

- Standardized, objective data for maintenance

- More expertise for asset management

- DAC-compatible

- Lower costs

- Faster turnaround times by increasing terminal capacities

- Realization of 1-person operation

- Documentation

- More efficiency

- Attractive & safe work

Strong future prospects: ABT is mentioned as a relevant application in numerous initiatives, for example at https://tis.ag/3-intelligenter-gueterzug/ . For SBB Cargo, ABP is one of the 3 key technologies for the implementation of 1-person operation.

Contact:

Felix Egger-Cimenti

[email protected]

+43 676 4048663

Do you have questions about our digital technology?

Simply fill in the form or contact Felix Egger-Cimenti directly.